+86 4008836695 (24 hours service)

+86 4008836695 (24 hours service)

+86 4008836695 (24 hours service)

+86 4008836695 (24 hours service)

| Alignment method | Active Clad-Alignment |

| Applicable fiber type | SM(ITU-T G.652&G.657) / MM(ITU-T G.651) / DS(ITU-T G.653) / NZDS(ITU-T G.655) |

| Compatible Fiber/Cable | 0.25~3.0 mm / leather cable |

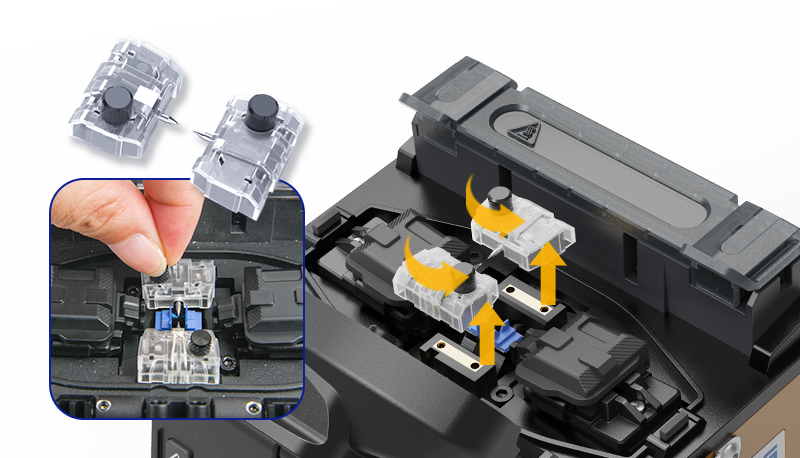

| Fiber Holder | Replaceable universal fixture, SOC fixture (optional) |

| Fiber Diameter | Cladding diameter: 80-150um, coating diameter: 100~1000um |

| Fiber Cleave Length | 8-16 mm |

| Splicing mode | Maximum 128 groups |

| Typical Splice Loss | SM: 0.02dB / MM: .01dB / DS: 0.4dB / NZDS: 0.04dB / G.57: 0.02dB ① |

| Return Loss | >>60dB |

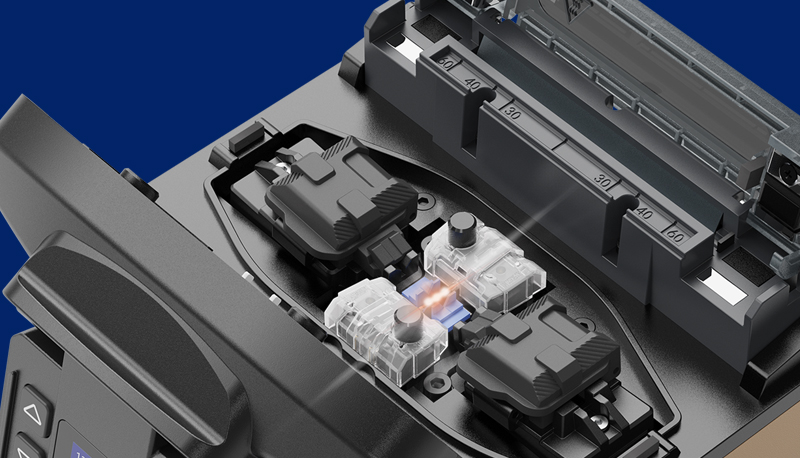

| Splicing Time | 6 seconds (SM G652 Quick mode) |

| Estimated Splice Loss | Available |

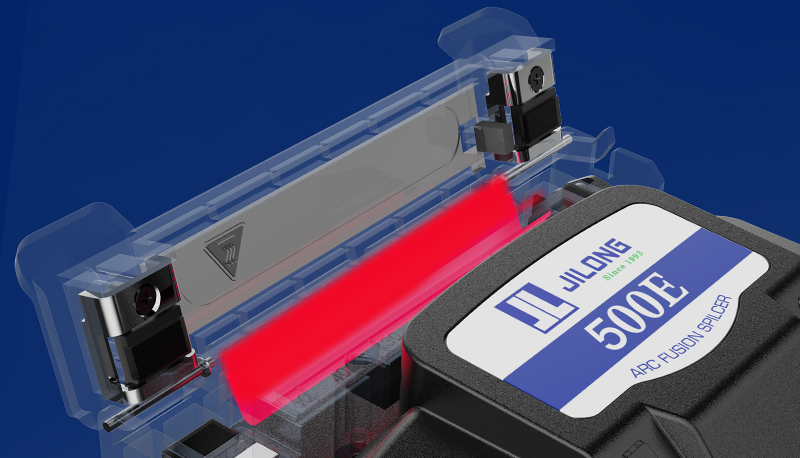

| Heating Time | Quick mode 18 sec.(SM G652 250μm 40mm Sleeve) adjustable★② |

| Protection Sleeve Length | 20mm, 30mm, 40mm, 50mm, 60mm |

| Heat Programs | Max 32 mode |

| Battery | 4000mAh Battery Capacity, Typical 120 Cycles (Splice&Heat) per Charge ★③ |

| Electrode Life | 5000 arcs (replaceable) ★④ |

| Auto-start | Splice / Heating |

| Automatic Fiber Identification | / |

| Automatic ARC Identification | Automatic arc calibration by air pressure and temperature |

| Results Storage | The last 10,000 splice records and 2,000 result images |

| Tension Test | Altitude: 0~5,000 meters, relative humidity: 0~95%, -20~50”C, maximum wind speed: 15m/s |

| Operating Condition | Altitude: 0~5000m, 0~95% relative humidity, -20~50°C, Max Wind 15m/s |

| Storage Condition | 0~95% relative humidity, -20~60°C |

| Display | 3.5” color high resolution (800 x 480) display |

| Fiber Magnification | X, Y, XY, X/Y : 320X Magnification |

| Power Supply | AC 100-240V, DC 9-14V |

| Terminal | USB2.0 |

| Weigh | 1.06kg without battery / 1.35kg with battery |

| Size | 130H x 113W x 126D mm |

★① With identical fibres(in room temperature). Measured by cut-back method relevant to ITU-T and IEC standards.

★② 0.25mm fiber,may vary depending on the battery status and operating environment.

★③ Splice & Heat cycles based on 40mm shrink tube.

★④ Electrode life may vary depending on the operating environment.